Fill Rate Challenges For Retail Trading Partners

By Victor Engesser, Retail Executive Advisor, RVCF

A Retail Value Chain Federation (RVCF) survey sheds light on how to drive fill rate performance improvements.

Optimal supply chain performance delivers speed, accuracy, and visibility. Retailer efforts to improve performance initially focused on many activities that suppliers could handle internally without significant retailer time and expense, such as EDI, ASN, on-time delivery, packaging, and labeling.

Optimal supply chain performance delivers speed, accuracy, and visibility. Retailer efforts to improve performance initially focused on many activities that suppliers could handle internally without significant retailer time and expense, such as EDI, ASN, on-time delivery, packaging, and labeling.

This was low-hanging fruit. The work done by suppliers yielded speed, efficiency, and lower expenses for retailers and were supported by scorecards, communications, and often compliance programs to drive adoption and recover even more expense. However, these efforts did little to improve fill rate performance. Providing full fill rate has proven to be much harder for suppliers to resolve on their own. Fill rate performance improvements require suppliers to get much better at planning production. This requires high-quality retailer forecasts and commitments to those forecasts.

The ability to close the sale every time because the exact item the customer wants is available for purchase, in the store or on the website, is a high priority and constant challenge for retailers. Purchase order frequency, store replenishment frequency, safety stock levels, and consumer demand variability are all factored into the equation by retailers when determining the right quantity to order to ensure optimal in-stock inventory.

If a retailer provides the merchandise supplier with this quantity information far enough in advance of issuing a purchase order, the accuracy of the forecast becomes an important part of the collaborative effort to improve fill rate performance. If not, the lack of a forecast, or a poor forecast with a high level of volatility, becomes a weakness and a less dependable planning tool for suppliers.

Although some retailers have solid forecasting capability, it appears many others have significant work to do. These retailers must address their internal IT systems and business planning processes to create a high-quality forecast that can be shared with suppliers as the first real step toward collaborative improvement. Regardless, many retailers already have scorecarding and compliance in place to force improvements from their suppliers, but this approach alone cannot solve the problem.

Retailers have made it clear that fill rate performance from their suppliers is not where it needs to be, and suppliers have made it clear that major obstacles must be overcome to achieve the necessary improvements. This spring, RVCF took a high-level look at the current challenges faced by retailers and suppliers as they work toward their mutual goal of full fill rate of purchase orders.

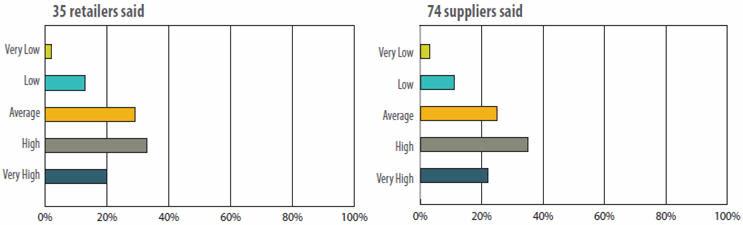

Across all your relationships with regard to performance, how big an issue is fill rate performance in your overall trading partner relationships?

Our initial survey solicited insights from both sides about the main issues and opportunities surrounding fill rate, as well as the level of importance they assign to related business processes. The findings of the survey, presented in this white paper, enabled us to identify areas of agreement and alignment, but also confusion and disconnect. This information will guide our next steps and help us craft a 2017 action plan for supporting RVCF members.

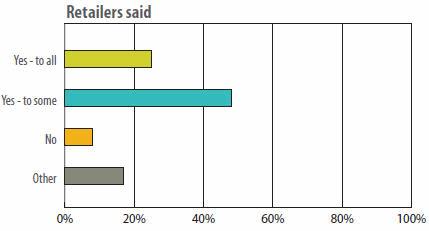

Do you currently provide forecasts to the suppliers you want better fill rate performance from?

Fill Rate Is Now A Front-Burner Issue

Fill rate is always a priority, but when it comes to the most important trading partner relationships in terms of revenue and margin, fill rate takes on a much higher level of importance for both retailers and merchandise suppliers. Our survey data suggests that fill rate performance is currently moving toward the top of the list of supply chain purchase order management challenges faced by trading partners.

If you look at past years, much work has been done, and much progress has been made, in addressing a variety of supply chain purchase order management issues, such as providing an accurate and timely ASN and improving on-time delivery. During that time, fill rate performance may have taken a back seat to problems that could be more easily improved. The reason might have been the significant effort required by a retailer to produce a high-quality order forecast and, in return, be in the position to expect a full purchase order fill rate. Now, it appears fill rate has become a front-burner issue.

What Are Retailers Doing To Improve Fill Rate Performance?

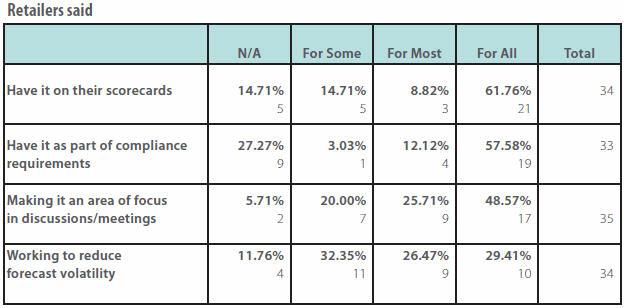

The majority of retailers are already measuring fill rate performance by making it a scorecard KPI and a part of their compliance requirements. Nearly half are making it an area of focus in discussions and meetings with suppliers. Clearly, attention is being given to this issue by retailers, and suppliers are constantly hearing about fill rate performance as an area in which retailers expect significant improvement.

Retailers also know they need to reduce forecast volatility. The efforts made internally by retailers to develop a better forecasting capability, as well as the collaborative efforts with suppliers to share and align around the forecast, will likely yield the highest potential for fill rate improvement.

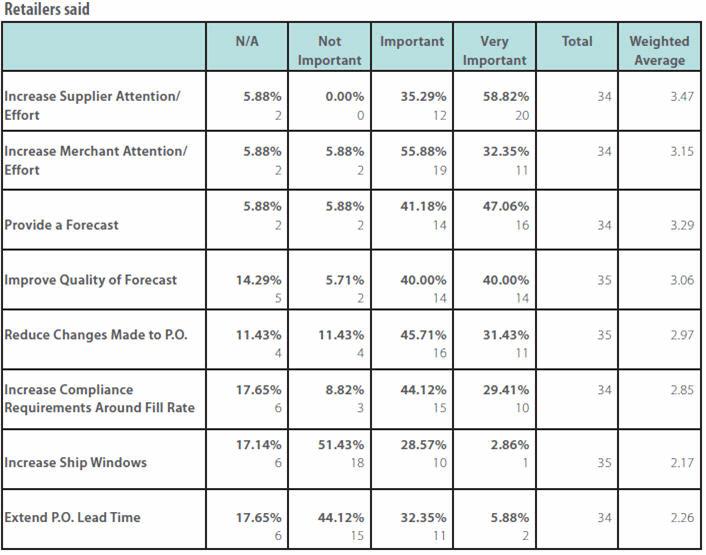

What Activities Do Retailers Believe Can Improve Fill Rate Performance?

Retailers are increasing attention and effort to achieve fill rate improvement, both internally and with their suppliers. However, according to supplier responses to our survey, two areas that would benefit suppliers – increased shipping windows and extended purchase order lead times — are not viewed as viable solutions by retailers.

Retailers have been working for years to get closer to “just-in-time” ordering and receiving, so they can better react to consumer demand patterns and optimize inventory productivity. Although adding more time back in would give suppliers more flexibility to expedite and jockey around available inventories, adding more time to the supply chain would be a step backward for retailers in inventory management, even if it helped to improve fill rate performance. In today’s retail environment, competitiveness requires speeding up, not slowing down.

Please tell us a little about how you are currently working to improve fill rate performance with your trading partners. (Please check all that apply.)

Eighty percent of retailers believe improving the quality of forecasts is either important or very important, which indicates that retailers understand the value of these efforts. This is where the real heavy lifting by retailers must be done. The right system software capability must be coupled with the right business processes designed to deliver a highly accurate forecast that can be shared with suppliers. Suppliers can then work backward through the production-planning process to ensure product is available to fill the purchase order.

From The Supplier’s Perspective, What Are Retailers Doing To Improve Fill Rate Performance?

While most retailers have made fill rate a compliance requirement, data in the chart below shows that some retailers are already taking important collaborative steps to improve supplier fill rate performance. The majority of suppliers said their retailer partners are working to improve order forecasts, committing to forecasts before ordering, and sharing more sales and inventory data. However, commitment is a two-way street in a collaborative relationship. If a retailer is willing to commit to a forecast, a supplier should be willing to commit to a fill rate.

The degree of variability tolerated in the order forecast by the supplier, as well as the actual purchase order quantity and upside or downside expected by the retailer to the order forecast, become a critical part of the collaborative negotiation between trading partners. As both partners plan together and get better at the forecasting process, this variability can be lowered, which will reduce financial risk and provide both partners with better inventory productivity.

What’s Keeping Suppliers From Improving Fill Rate Performance?

Reductions in purchase order lead times, short shipping windows, low-quality forecasts, and the lack of an order forecast altogether are obstacles to better fill rate performance. Less available time from forecast to purchase order to required delivery date will strain the supplier’s supply chain. Suppliers also admit that some fill rate problems are self-inflicted. Overselling their limited available inventory, and the way available inventory is allocated among retailers, can cause headaches.

Suppliers confirmed they need high-quality forecasts from retailers to plan production and fulfill orders. Suppliers also need assurance that retailers will stand behind their forecasts. Otherwise, risk increases for both partners, but especially for suppliers.

In a seemingly worst-case scenario, some suppliers responding to our survey said the biggest challenge to providing 100 percent fill rate is that forecasts are inaccurate, and retailers often place a purchase order that doesn’t align with the forecast. In some cases, suppliers are then hit with a chargeback for a fill rate violation. This is a prime example of what collaboration does not look like.

Suppliers need an accurate forecast, and they need retailers to stand by that forecast, even if it differs from the final quantity they want. If the retailer writes a purchase order for less than the forecasted quantity, the supplier is left with excess inventory. If the retailer writes a purchase order for more than the forecasted quantity, the supplier is forced to scramble to find additional inventory. As a result, the supplier must either overproduce to a retailer’s forecast or “borrow” from another retailer’s planned allocation.

This is a big reason why fill rate is such a challenging issue. There can be tremendous risk involved. If there is too little inventory available, sales are lost for both trading partners. If there is too much inventory available, margins for both trading partners suffer as markdowns are taken to sell-through. In less collaborative relationships, whoever is left holding this excess inventory can be exposed to significant unplanned costs.

Please rate the importance of each of the following activities you may be using to improve fill rate performance.

Will Fill Rate Performance Get Better?

Our survey suggests improvement is coming. Half of retailers and more than half of suppliers expect fill rate performance to get better. Activities within both retailer and supplier organizations, as well as collaborative efforts among trading partners, are raising awareness and changing behaviors.

Although there is plenty of optimism, comments from retailers and suppliers indicate that this will not be an easy or painless process. Getting tougher won’t solve fill rate problems, and neither trading partner can realistically force an incomplete solution onto the other. Comments confirm that business process improvements, better communication, deeper data sharing and, most importantly, an understanding of risk and shared risk management are required to deliver collaborative improvements in forecasting, purchase order management, and supplier fill rate performance.

The Role Of Service Providers

Retailers and suppliers rely heavily upon service providers to off er technological solutions and services that improve accuracy, reduce errors, simplify operations, and facilitate seamless communication and information sharing.

There is more than one methodology to produce a forecast. Trading partners must come to an agreement with regards to the methodology and the type of forecast being used. Service providers must be able to speak intelligently about not only the tools and services they off er, but the methodology being used. Retailers and suppliers must be fully educated about the differences in methodology before choosing a solution.

There are also various EDI documents that support forecasts. The majority of retailers aren’t creating or sharing these documents with suppliers. If the retailer doesn’t indicate that a particular document is mandatory or whether that document is even offered, the supplier won’t do the necessary mapping. EDI service providers should push for the introduction of EDI documents and explain how trading these documents can improve adoption. Having information about inventory and setting proper expectations will help to strengthen the trading partner relationship and drive higher fill rate performance.

Finally, service providers need to enhance or create better forecasting tools that provide retailers and suppliers with the ability to measure the right information, reduce forecast volatility, better manage inventory, and improve fill rate performance.

Conclusion

For the remainder of 2017, RVCF will continue to drive initiatives to support fill rate performance improvements. This will require us to identify and drill down into many of the nuts-and-bolts issues that contribute to known supplier difficulties. We’ll also collect data and provide insights into what can and should be done by both retailers and suppliers to address these issues. Discussions at RVCF conferences will be centered on these topics, which include but are not limited to:

- Port delays and dock strikes

- Weather-related interruptions

- Shorter routing request notice windows

- Retailer-specific product prep expense on forecasted but nonordered inventory

- Fill rate measurement at the SKU rather than “style” level (apparel)

- Lack of use of EDI documents supporting forecast communications (such as 830o and 830i)

Our goal is to bring retailers, suppliers, and service providers to the table, listen to the concerns and ideas of all parties, conduct further research, and use this information to determine best practices for improving fill rate performance. We encourage all retail industry stakeholders to participate in these initiatives and help to drive positive change in a way that benefits all parties involved.